5 Things You Should Know About The Semiconductor Shortage Affecting The Car Industry

Published On May 24, 2021 04:20 PM By Sonny

- Write a comment

The crisis delaying production, deliveries, and new launches will take longer to fix than you think

The global pandemic has affected the Indian automotive industry in more ways than one and the shortage of semiconductor chips is likely to have a prolonged impact. Let’s look at how this problem is affecting the car industry, how carmakers are responding to it, and what it means for buyers.

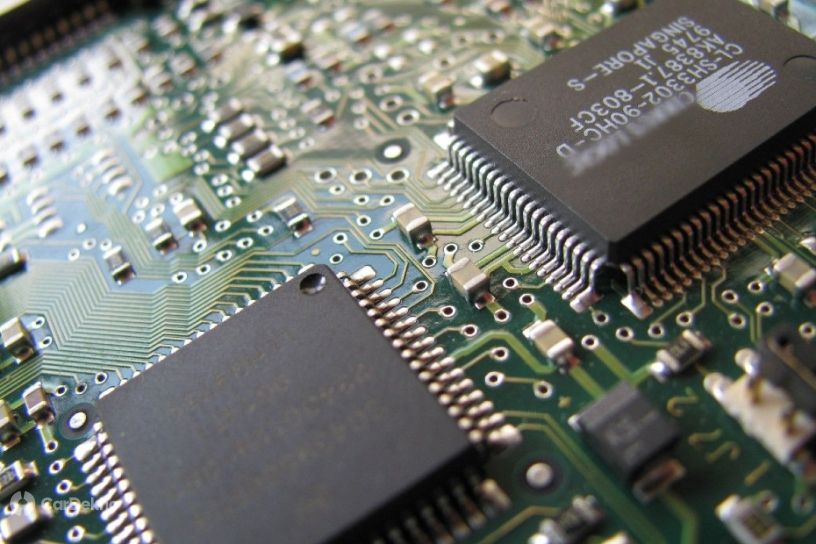

What is a Semiconductor Chip?

All modern cars, even the low-budget mass-market models, are fitted with plenty of electronics and circuits. These circuits aid the functioning of various features including power steering, power windows, climate controls, infotainment systems, and the car’s own ECU (electronic control unit) that helps ensure the mechanical bits are running properly and being monitored. Semiconductor chips are key components for all such circuits as well as most modern electronic appliances.

Related: Here’re the Five Most Affordable Cars That Come With Wireless Apple CarPlay And Android Auto

Why are Carmakers Facing a Shortage of These Important Chips?

Most manufacturers usually maintain a limited inventory of semiconductors, enough to keep up with the rate of production at their facilities. During the first wave of the pandemic when many countries announced nationwide lockdowns, carmakers who were stuck with low demand and high inventory altered their orders for these chips. Only a few companies around the world manufacture these chips at scale and they usually prefer electronics companies over carmakers as the former use more high-end chips that offer high margins. When economies began to reopen, automakers were flush with new orders due to pent-up demand. They needed a lot more semiconductor chips to meet those demands but the chipmakers had dedicated their resources towards other industries that placed orders first. So, now, carmakers are running short on this key electronic component which has led to costly delays.

How Will This Shortage Affect Car Buyers?

We’ve already seen the effects of the semiconductor shortage with the likes of the Mahindra Thar. Units were almost entirely ready but were missing their infotainment systems, a component delayed by the chip scarcity, and hence could not be delivered to customers. That was at the start of 2021. As the crisis continues, carmakers are taking drastic measures. Across the world, some have had to temporarily suspend production or reduce shifts across factories, such as Nissan in Japan and Ford in the US. Some brands are also shrinking the equipment list of models to reduce the number of chips needed for each unit. This not only causes delays in current delivery times but also postpones the launch of new cars such as the Mahindra XUV700. The costs incurred by carmakers due to this supply disruption would eventually be borne by customers.

- Upcoming Car Launches That Are Now Delayed

- Here’s How Much You’ll Have To Wait For A Sub-Compact SUV In These 6 Metro Cities

How is the Industry Combating the Issue?

Automotive brands are looking for alternative sources of semiconductor chips and electrical components for their cars to deal with the current shortage and avoid a similar crisis in the future. Since existing foundries are already operating at max capacity, there is a need for new players to build chips for cars. Leading electronics manufacturers such as Intel, Foxconn, and even Huawei are working with carmakers to meet their chip requirements and offer new tech-based features in the future. Meanwhile, Korean brands Samsung and Hyundai are looking to enter into a partnership for the same. Many of the chips from these electronics brands will be for EV models as they use more modern technology than the average combustion engine model.

Also read: Jeep And PSA Tie Up With Foxconn To Develop Digital Cockpits And Connected Services

Is the Chip Shortage Nearly Over?

The short answer is no. Not quite. Many industry experts have reason to believe that this deficit could easily continue into 2022 and maybe even until mid-2022. As countries reopen and electronics manufacturers enter the fray, it will take time to set up new production and assembly facilities to build chips for cars as they have their own distinct specifications. There is also the matter of pending orders and delayed product timelines. So it’s safe to say it will be a while before the issue is completely resolved.

4 out of 4 found this helpful