Technical Aspects: Dry Sump Lubrication

Modified On Feb 25, 2016 12:03 PM By Sahib

- Write a comment

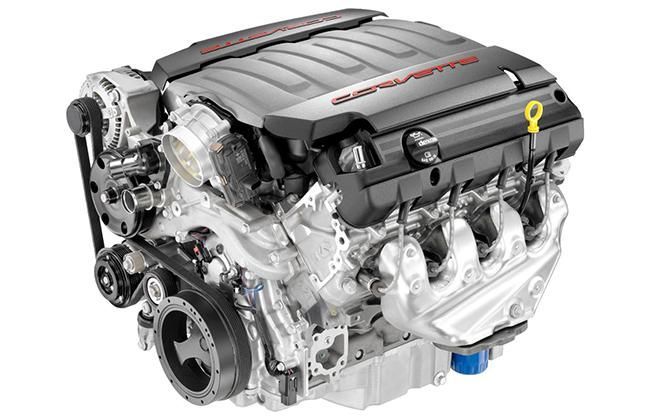

Dry sump lubrication systems are commonly used with high performance production cars like Audi A8, Corvette ZR1 and Porsche 911. The main purpose of the dry sump system is to contain all the stored oil in a separate tank, or reservoir. It involves pumping the oil from the sump to the separate tank (leaving sump dry) and then oil is pumped from the tank to lubricate the engine. The minimum amount of oil possible remains in the engine. Oil pumps are used for this purpose.

Technical Facts:

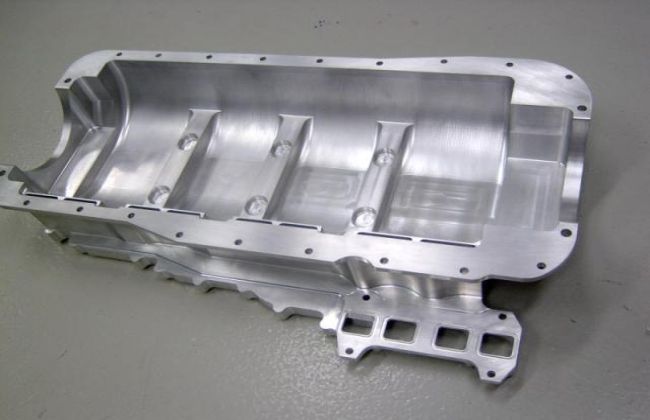

1. The main components of typical dry sump lubrication system are: oil storage tank, oil feed line, oil pumps (2 pumps) and oil return line.

2. The oil from the storage tank is fed to the pressure pump which pumps it under pressure into the engine via oil feed line. Oil strainer is also there which prevents dirt and debris in oil to enter the oil feed line.

3. The oil after entering the engine lubricates the moving parts of the engines and the bearings. Finally the excess oil collects in the sump and is return to the oil storage tank by the scavenge pump via oil return line. This keeps oil sump essentially dry.

4. With very little oil in the pan, the rotating assembly gets rid of windage, which is a phenomenon in which rotating components are burdened with the weight of excess oil. Keeping the rotating assembly free of windage allows it to spin freely and make more power.

Advantages:

- Since the bulk of the oil is not stored in the pan, the engine can be installed lower in the vehicle. This lowers the vehicle’s center of gravity.

- Oil has a better place to cool as it is being stored in a separate tank away from hot engine.

- More power, as there is no windage.

Disadvantage:

- More complex and expensive.

Watch this video for better understanding of Dry sump lubrication: