How To Build a Limousine

Modified On Oct 20, 2015 01:28 PM By Nabeel

- 2 Comments

- Write a comment

How does someone define luxury, in words one might say comfort, space, music, climate, quality, company and the most important, style. All these factors can be easily found in a 5 star hotel or a luxury condo. But what if someone demands all these features on wheels, not to worry, we have our tried and tested limousines. From jacuzzis to heated swimming pools, from sun roofs to helipads, limousines have them all. Made exactly to the owner’s specifications, these mechanical marvels are truly luxury on wheels. The longest limousine in the world is called The American Dream and is 30.5 meters long (6 times the average sedan) and has 26 tires, room for a lot of passengers, a heated Jacuzzi, sun deck, swimming pool, a few beds and a helipad.

Also Read: Evolution: Toyota Corolla

While The American Dream uses hinges in its body to turn, there are more practical solutions too. Almost any car you own can be made into a limousine. Its fairly simple, strip the car’s interior, cut it from the center, add lower and upper rockers, finish the bodywork and interiors, and you have a stretch. All this process takes about 2 to 3 months and about 40 trained workmen working 16 hours a day adding 1000 meters of additional cables and 350 kg of steel. Lets discuss these steps in detail to learn how to make a limousine, but first, lets go over some important points.

A. Do not stretch the car beyond 120 inches, it will make the car unstable and overheat the engine

B. Make sure your car has a heavy duty chassis, axles, transmission, power steering and wheel bearings, if not, replace the same

C. Upgrade the car’s suspension to support the weight of the new modification

D. Mount the car on a trolley which moves on straight guide rails to ensure a perfect stretch

E. The entire car should be first designed on a CAD software starting from a line diagram of the car.

Now that we know the necessities to be covered, let's get down to business. The transformation from a car to a stretch involves 5 steps.

1. Stripping and Covering

The interior car needs to be stripped to its bare bones, leaving only the dashboard and the boot attached. Dashboard holds complicated electronics and should not be messed around with.

All the other parts which are not removed from the car should be covered with a layer of plastic sheet to protect it from machining residue.

2. Cutting

Cutting is the most fun and the most important part of the build. Cuts should be precise and at exact locations from the zero point of the car to ensure best stability. An offset of 10 inches between the top and the bottom cut is advised to ensure stability.

Also Read: The Indian dream: Great concepts cars of Indian origin

After marking the cut points, reinforce the body with cross beams on both sides of the cut to ensure roof stability. After welding the cross beams, make the cuts with precision.

3. Extending

After the cut, pull the trolley holding the front of the car to the desired length. Add Roof rails and lower rockers between the two parts. The lower rockers are made of 3 steel (320 gauge) plates welded together for maximum strength.

Connect the roof rails and add the factory pillars in the center of the stretch. Do not forget to add a safety bar along the side of the stretch to protect its occupants from side impact.

4. Bodywork and Interiors

After reinforcing the chassis, remove the cross beams and install the floor(16 gauge steel) making adequate room for the drive shaft installation. The roof is made out of hardened foam reinforced with fiberglass. The interior is further coated with insulations of jute.

The floor coating is thicker in order to provide proper sound and heat insulation. Driver’s cabin is isolated with a fiberglass wall usually equipped with a TV screen and speakers. Interiors are custom made according to the customer’s specification. An extra battery(marine) is added in the interiors to support the additional features. The final straw is paint. Paint usually takes about a week and is done to the owner’s specifications.

5. INSPECTION

A detailed inspection is conducted testing each and every feature of the build. The limousine is tested in both dynamic and static condition to ensure a perfect product.

Also Read

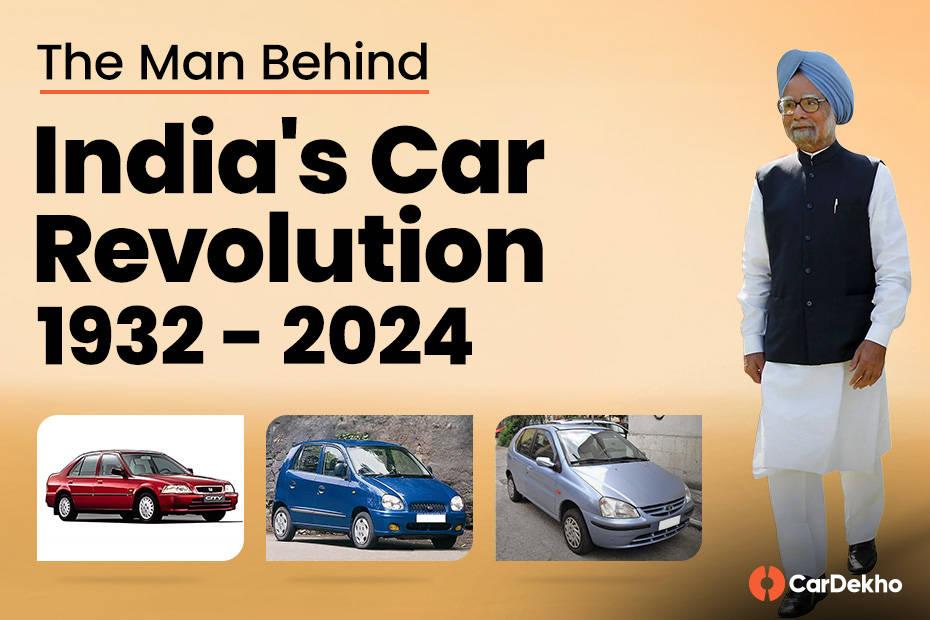

Truly Indian Cars Since Independence